The Benefits of Using AI for Logistics Forecasting and Demand Planning

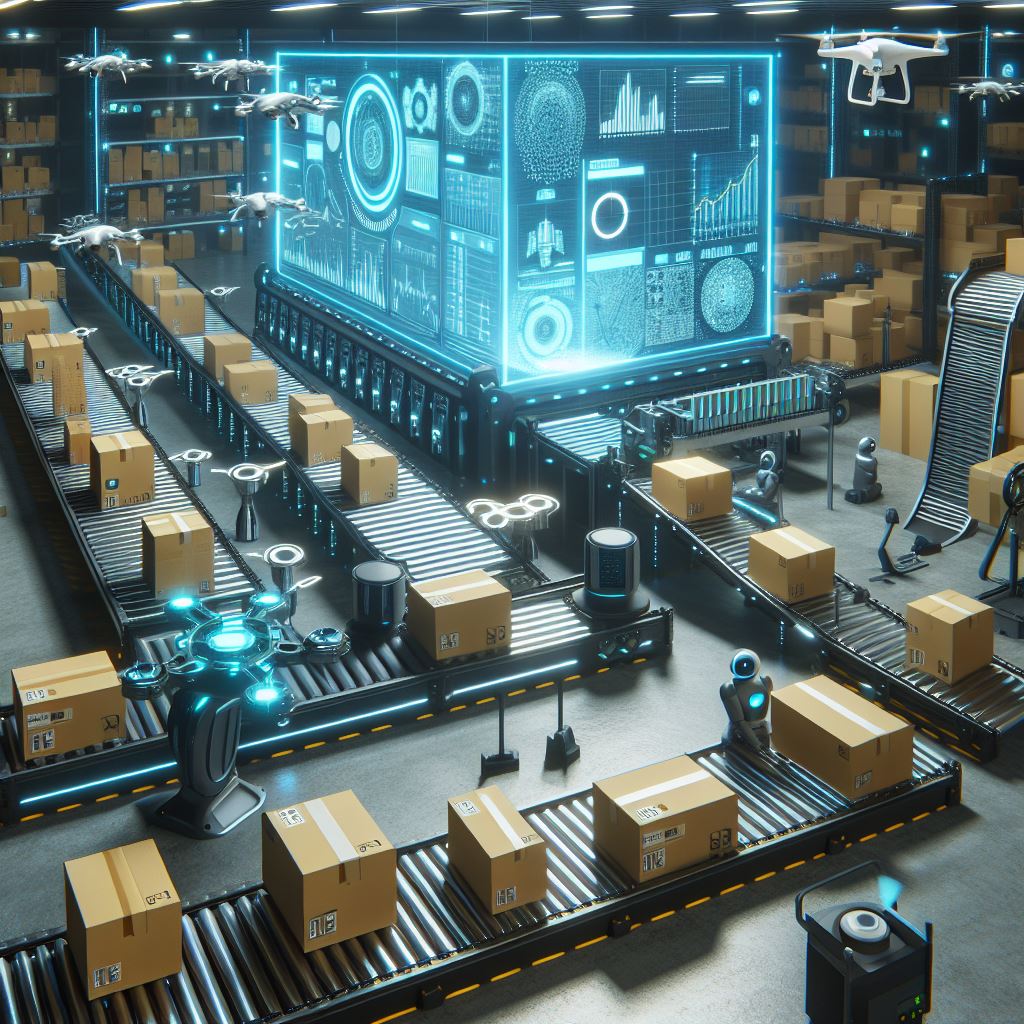

Staying ahead of the competition is critical to success when it comes to logistics. Logistics forecasting and demand planning are important factors that can make or break a logistics organization. Accurate forecasting of product demand optimizes inventory management and improves supply chain efficiency. In recent years, artificial intelligence (AI) has emerged as a game changer in logistics forecasting and demand planning, transforming the way logistics organizations work.

Traditional methods relied on historical data and statistical models. While these ways served as a foundation for forecasts and planning, they needed help adapting to the market’s dynamic nature today. This is where AI comes in, enabling logistics companies to evaluate massive amounts of data in real-time and extract important insights. In this blog post, we’ll discuss the advantages of AI in logistics forecasting and demand planning.

What is Logistics Forecasting?

Logistics forecasting is the practice of estimating how many units of your product will be purchased in the future. Historically, the logistics forecasting function has used previous data to anticipate future demand. This is frequently how demand planners or buyers define logistics forecasting, but it ignores a critical assumption. This factor is if your customers are interested in those product lines.

An improved definition of logistics forecasting provides a small but necessary change. This change is that logistics forecasting is the practice of estimating how many customers are interested in purchasing your product. The essential distinction between the two definitions is the incorporation of a customer-first mindset. Consumers drive demand, and predictions must show consumer behavior much as they do historical sales trends.

Logistics forecasting is a scientific and data-driven practice. It marks the beginning of an organization’s fundamental theory for the whole supply chain. However, it must still be adjusted and executed with careful preparation.

What is Demand Planning?

Demand planning is the overall management of resources to meet expected demand. This is where demand planners put their forecasts into action, preparing new orders and distribution operations. It is a complex task that takes expert planners to complete successfully.

It is also a significant point in the forecasting lifecycle. After using the process to predict future demand, demand planners work with marketing and sales teams to adjust the projections. This can help refine unconstrained demand expectations. The planner also collaborates with their fulfillment or supply chain team to determine what can be completed in the allotted time frame. This reduces the projection to a limited logistics forecast.

How are Logistics Forecasting and Demand Planning Different?

Logistics forecasting is the act of estimating consumer interest in purchasing a specific product, whereas demand planning is the management of resources to meet the predicted demand. Logistics forecasting and demand planning are often confused with one another. The most common source of confusion is the function of a demand planner, who is responsible for both forecasting and planning. However, dividing roles and procedures allows for forecasting and planning to receive specialized resources, tools, and training.

Benefits of Using AI in Logistics Forecasting and Demand Planning

AI-driven inventory planning tools have several advantages over traditional inventory planning solutions. These methods reduce manual calculations and human errors, ensuring that businesses order the proper amount of stock at the right time. This is independent of seasonality, promotions, supplier lead times, or other circumstances. Here are some of the advantages that AI logistics forecasting and demand planning bring to the inventory planning process.

Improved Accuracy and Efficiency

AI systems excel at analyzing enormous datasets, recognizing patterns, and making very accurate predictions. This translates into more precise future demand estimates. By taking into account a wide range of variables such as past sales data, market trends, weather patterns, and even social media sentiment analysis, AI models can provide projections that are not only accurate but also reflect the intricate interplay of elements that influence demand. Third-party experts such as RTS Labs can help you successfully set up and streamline AI-powered data management systems.

Adaptability

Unlike traditional methods, which frequently use static models, AI-powered solutions can change in real time. This agility is critical in the dynamic world of logistics, where demand shifts or unanticipated disruptions can have serious effects. AI systems are always learning from fresh data, allowing them to adapt forecasts as situations change. This real-time adaptability allows logistics organizations to make informed decisions quickly, managing inventory levels and ensuring on-time delivery.

Reducing Costs

Accurate forecasting and demand planning help optimize inventory levels, lowering the risk of overstocking or stockouts. Overstocking ties up cash and warehouse space, increasing holding costs, whereas stockouts result in lost sales opportunities and possibly consumer displeasure. AI-driven forecasting and demand planning reduce inefficiencies, resulting in significant cost savings for logistics companies.

Customer Satisfaction

Timely and accurate delivery is critical in the logistics industry. Companies may optimize their supply chains and improve delivery timeframes by using AI forecasting and planning models that provide better visibility into future demand. Consistently meeting client expectations increases customer satisfaction and loyalty. This great client experience can lead to repeat business and favorable word-of-mouth, therefore improving a company’s reputation.

Better Strategic Planning

AI is useful not just for operational efficiency, but also for strategic planning. Long-term trends and industry developments can help logistics organizations make informed decisions about capacity expansion, new market entry, and product diversification. The capacity to look beyond the immediate future enables businesses to position themselves strategically in the market and obtain a competitive advantage.

Scalability

Logistics forecasting and planning necessitates evaluating and processing massive amounts of data from a variety of sources. These include sales records, customer behavior, weather trends, social media, and others. AI algorithms can handle this size with ease, allowing businesses to expand their operations without concern for resource limits.

Variability Management

Demand for products or services in the logistics industry can be highly volatile due to seasonal swings, promotions, or unanticipated events such as the COVID-19 pandemic. AI-based models can capture and account for this unpredictability, allowing businesses to alter their inventory levels, transportation plans, and resource allocation accordingly. This lowers the risk of stockouts, delays, or excess inventory, resulting in higher customer satisfaction and profitability.

Automation

AI forecasting and demand planning tools can work with all of your data sources to automatically update purchasing suggestions based on the most recent information. AI technologies can account for future sales forecasts, current stock levels, any supply chain delays, and any other demand or supply restrictions to ensure your replenishment strategy is always correct.

Managing Supplier Unpredictability

Effective inventory planning is strongly dependent on the ability to accurately forecast supplier lead times. As supply networks become more complicated and unpredictable, timetables that were once dependable are now subject to regular delays and variations. These variations might potentially upset your inventory planning procedures. AI tools may automatically apply new lead time information to ordering plans, ensuring that they are correct and up to date.

Simulating Historical Sales Data

To maintain an effective ordering strategy, organizations must be able to reliably forecast demand based on solid past sales data. However, for certain products, such as new SKUs with no sales history, this may be impossible. Advanced algorithms and AI capabilities can be utilized in dynamic inventory planning software to generate a demand forecast model based on similar products, which is automatically updated as new data becomes available.

Drawbacks of Using Artificial Intelligence

While AI forecasting and planning provides various benefits to retail, e-commerce, and wholesale organizations, it also presents several obstacles. Purely AI-based solutions necessitate powerful algorithms to act as safeguards against possibly incorrect data. AI demand forecasting necessitates precise and relevant data. If the historical data used to train the AI model is inadequate, incorrect, or does not reflect current market conditions, the projections generated will be unreliable.

AI algorithms may struggle to identify unexpected patterns or shifts in customer behavior that did not appear in the training data. When dealing with new market conditions, this might lead to missed opportunities or wrong estimates. Moreover, AI models frequently require constant upgrades and recalibration to remain relevant. As market conditions change over time, failure to update AI models might result in declining forecasting accuracy.

Integrating AI forecasting technologies with current legacy systems and procedures can be challenging and time-consuming. Poor integration might result in data conflicts and inaccurate forecasting outcomes. Additionally, some AI solutions may not be easily configurable to meet individual business demands, resulting in generic projections that may not reflect the company’s unique qualities.

Final thoughts

Logistics forecasting and demand planning are critical to the success of any logistics business. Effectively anticipating the needs of customers and the products they are likely to purchase along with proper planning to acquire and manage all the resources necessary to meet that demand is crucial to put yourself ahead of the competition in the evolving logistics industry. The use of artificial intelligence is the most effective strategy to achieve this outcome.

AI will help your business reduce costs, improve efficiency, and increase customer satisfaction. It also helps you scale your company to meet increasing demands and manage changing customer behaviors and market conditions. There are some drawbacks to the implementation of AI, but the benefits significantly outweigh the challenges.

If you are looking for support with implementing AI into your forecasting and planning procedures, look no further than the experts at RTS Labs. If you are ready to revolutionize your logistics operations with AI consulting, contact us!