Most supply chain failures don’t happen in the warehouse. They start in the forecast.

When demand predictions are off, everything downstream suffers: production misfires, inventory piles up in the wrong places, and transportation costs spike. Poor forecasting accuracy alone can inflate supply chain costs.

Automation changes this equation. With AI-driven forecasting, real-time data feeds, and automated decision flows, companies can prevent breakdowns before they begin. This article shows how supply chain automation creates the accuracy, speed, and resilience modern operations demand, and where RTS Labs helps teams finally turn fragmented data into coordinated action.

What Is Supply Chain Automation?

Supply chain automation is the end-to-end use of digital systems, data intelligence, and automated workflows to streamline how goods, information, and decisions move across the supply chain.

It goes beyond simply adding AI or robotics to streamline logistics. It redesigns how supply-side processes function, removing manual intervention from planning, procurement, sourcing, inventory control, warehousing, transportation, and fulfillment.

When automated, the supply chain can sense changes, respond instantly, and adjust operations without human delays.

How Supply Chain Automation Is Transforming Businesses

Supply chains used to rely heavily on manual updates, phone calls, spreadsheets, and human judgment at every step. As operations scaled and demand became more unpredictable, these manual processes created friction, delays, and visibility gaps across sourcing, procurement, warehousing, and logistics.

Automation changes that by turning supply chains into connected, responsive systems that can operate faster and with far fewer errors. Below are the biggest transformations automation is driving across the modern supply chain.

Increased Efficiency and Faster Cycle Times

KPMG finds that 80% of the leaders find their organization’s inability to adopt automation makes them slower than competitors.

Automation streamlines repetitive tasks like purchase order creation, inbound receiving, shipment scheduling, and replenishment planning. Companies using automated workflows see faster supply chain cycle times. This speed is especially critical in industries where delays ripple across production, distribution, and customer fulfillment.

Smarter Inventory Management Across Facilities

Automated systems continuously monitor stock levels, supplier lead times, and consumption patterns, triggering replenishment at the right moment. Automated inventory systems reduce stockouts and cut excess stock to directly improve working capital, warehouse utilization, and customer service levels.

Higher Accuracy and Fewer Manual Errors

Supply-side processes that depend on manual data entries, such as order quantities, SKU codes, and freight bookings, often create downstream issues. Automation eliminates these error points. Automated data handling can reduce transaction errors to near zero. Fewer errors mean fewer corrective actions, fewer shipment issues, and fewer customer service escalations.

Lower Operational Costs Across Procurement, Warehousing & Logistics

When automation handles tasks like PO approvals, invoice matching, routing, dock scheduling, and returns processing, labor loads drop significantly. Automation also reduces detention fees, rework, write-offs, and expedited shipping.

End-to-End Visibility From Supplier to Customer

Real-time data from suppliers, warehouse systems, logistics partners, and IoT sensors gives organizations a complete, continuous view of supply-side operations. McKinsey found that digitally connected supply chains reduce disruption impact by up to 50%. Visibility prevents surprises and enables proactive responses to delays, shortages, and supplier risks.

More Accurate Demand & Supply Planning

Predictive models combine historical data, market signals, seasonality, and supplier performance to anticipate needs early. Predictive planning improves forecast accuracy, leading to better sourcing decisions, smoother production cycles, and fewer last-minute shortages.

Here’s a table comparing a supply chain with and without automation:

| Area | Without Automation | With Automation |

|---|---|---|

| Inventory Management | Frequent stockouts, overstocks, and manual cycle counts | Predictive replenishment, real-time visibility, and fewer stock issues |

| Demand Forecasting | Spreadsheet-driven, slow, error-prone | AI-driven forecast accuracy |

| Operational Speed | Manual approvals, delays across procurement & logistics | Faster cycle times via workflow automation |

| Order Accuracy | High error rates in PO creation, picking, and routing | Near-zero errors with automated data validation & smart warehousing |

| Logistics Efficiency | Reactive routing, frequent delays & last-minute firefighting | Dynamic routing, load optimization, and fewer delays |

| Supplier Performance Management | Inconsistent communication, limited visibility | Automated scorecards, risk alerts, and real-time tracking |

| Cost Structure | Higher labor, warehousing & transportation costs | Cost reduction across operations |

| Visibility | Fragmented data across ERP/WMS/TMS | Unified, end-to-end visibility from supplier to customer |

| Risk Management | Slow detection of disruptions | Real-time alerts, predictive risk modeling, and faster mitigation |

| Scalability | Processes break under volume | Systems auto-scale as demand & operations grow |

What are the Key Components of Supply Chain Automation

Modern supply chain automation is an ecosystem of connected capabilities that work together to streamline planning, sourcing, warehousing, transportation, and fulfillment. These components transform fragmented, manual workflows into unified, data-driven operations where decisions are made in real-time.

Below are the foundational building blocks of an automated supply chain.

Data Integration & Unified Visibility

Supply chains generate data across ERP systems, WMS/TMS platforms, supplier portals, transportation networks, IoT devices, and customer channels. Automation begins with connecting these fragmented systems into a single source of truth.

This allows real-time visibility from suppliers to distribution centers, faster decision-making across procurement, replenishment, and logistics, and automated exception alerts when delays or shortages occur.

Workflow Automation (RPA + Intelligent Decisioning)

Workflow automation replaces manual, repetitive tasks across the supply side for

- Automatically creating purchase orders

- Matching invoices with POs and receipts

- Scheduling docks or carrier pickups

- Updating inventory records

- Routing shipments

When combined with AI, workflows start making context-aware decisions, such as selecting alternate suppliers or adjusting order quantities.

Predictive Analytics & AI Forecasting

AI models analyze historical data, supplier performance, demand signals, and market trends to predict what will happen next, which allows companies to automate demand forecasting, inventory optimization, supplier risk scoring, lead time predictions, and production planning.

This level of foresight minimizes shortages, reduces waste, and aligns planning with real-world fluctuations.

IoT, Sensors & Real-Time Tracking

IoT devices and RFID tags track the location, condition, and movement of goods in real time.

Supply-side IoT enables automation in:

- Asset tracking across warehouses and transit

- Temperature monitoring for cold-chain logistics

- Real-time shipment condition alerts

- Predictive maintenance for machinery and fleets

AI-Powered Planning & Autonomous Decision Systems

These systems support “lights-out” operations, continuously analyzing data and taking action without waiting for human intervention. This is where automation becomes truly proactive.

AI agents can recommend order quantities, reroute shipments based on delays, balance inventory across warehouses, trigger replenishment workflows, and identify at-risk suppliers.

Robotics & Smart Warehousing

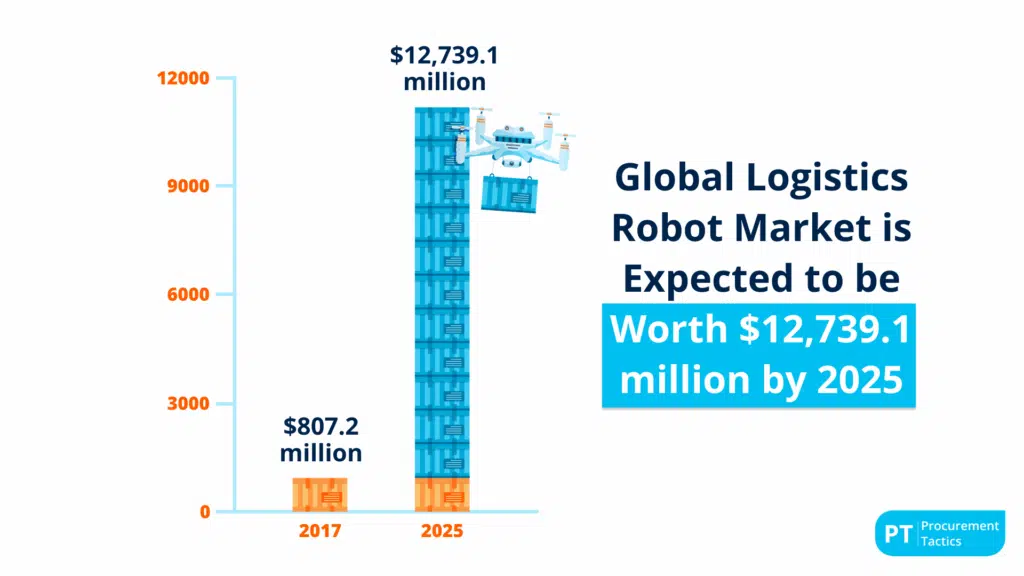

The Global Robotics Market Outlook findings say that robotics in the supply chain is expected to grow at 14% annually through 2026. While not required for every organization, robotics enhances warehouse automation with autonomous mobile robots (AMRs), robotic picking arms, and automated sorting and packing.

Exception Management & Automated Alerts

Automation is not just about doing things quickly. It’s about resolving problems before they escalate to help supply chain teams shift from firefighting to proactive control. Exception-based automation flags late supplier shipments, low inventory thresholds, warehouse congestion, delivery delays, damaged or spoiled goods, and compliance failures.

How Supply Chain Automation Works

Supply chain automation follows a structured, end-to-end process that connects data, systems, and actions across procurement, warehousing, logistics, and fulfillment. Think of it as a continuous loop where the supply chain can sense → interpret → decide → act, with minimal human intervention, increasingly, in real time.

Below is a step-by-step breakdown of how automated supply chains operate at each stage.

1. Data Collection Across the Supply Chain

43% of organizations report having no visibility of tier one supplier performance reports, according to KPMG. Automation starts by gathering real-time data from every touchpoint, including:

- ERP systems: orders, POs, invoices, etc.

- WMS/TMS platforms: inventory, shipments, routes, etc.

- IoT sensors & RFID tags: location, temperature, equipment health, etc.

- Supplier portals: lead times, confirmations, delays, etc.

- Customer channels: demand signals, returns, etc.

For example, a cold-chain logistics company can collect temperature data from sensors inside refrigerated trucks. If the temperature exceeds the threshold, the system flags an exception immediately.

2. Data Unification and Cleansing

Before automation can execute decisions, data from fragmented systems must be standardized into a unified view. A retailer can integrate data from Shopify, NetSuite, and its warehouse scanning systems. RTS Labs builds a data pipeline that unifies product codes and order IDs so automation can work reliably.

Data unification and cleansing involves cleaning duplicate or incorrect data, matching SKUs across systems, normalizing supplier and order records, and building a unified data model.

3. AI/ML Models Analyze Data & Predict Outcomes

Once the data is unified, AI models detect patterns and generate insights such as demand forecasts, supplier risk scores, optimal reorder points, predicted stockouts, route delays or bottlenecks, and inventory redistribution needs.

For instance, a manufacturer’s ML model predicts a spike in demand for certain components based on seasonal trends and recent sales acceleration weeks before the spike occurs.

4. Automated Workflows Execute Supply Chain Actions

Insights trigger automated actions via RPA, workflow engines, or API-based automation.

Some examples where automated actions can prove efficient are:

- Auto-replenishing inventory when levels drop

- Auto-generating purchase orders and routing them for approval

- Auto-assigning carriers based on capacity and cost

- Auto-booking dock slots

- Auto-updating customers about delivery ETAs

5. Real-Time Monitoring & Exception Handling

In 2023, tracking and reporting metrics were the top priority for supply diversity leaders as per a Scoutbee survey. Automation helps to catch problems early. Exception-based alerts trigger human review only when needed, such as in the case of supplier delays, temperature deviations, equipment failures, shipment congestion, and inventory discrepancies.

6. Continuous Feedback Loop for Self-Improvement

As automated systems execute actions, the data feeds back into the models, improving future predictions, which helps to increase forecast accuracy, automatically reorder points, adjust supplier performance scores, lead to more precise lead times, and improve routing and load planning.

For example, RTS Labs helped a global sports equipment manufacturer untangle a fragmented data architecture that was slowing growth and blocking advanced analytics.

By implementing a modern data lake, removing coding bottlenecks, and centralizing data ingestion, the company gained faster access to insights, reduced internal costs, and cut company-wide spending by 25%.

7 High-Impact Use Cases of Supply Chain Automation

Automation is no longer limited to warehouses. It extends across the full supply chain lifecycle, from forecasting and sourcing to logistics and reverse operations.

Below are seven of the most valuable, high-ROI use cases transforming modern supply chains.

1. Automated Inventory Replenishment

Automating replenishment eliminates guesswork by continuously monitoring stock levels, lead times, and consumption rates, then triggering restock decisions before shortages occur.

This creates a more stable inventory environment that lowers safety-stock requirements and prevents operational delays. Walmart’s replenishment automation, for example, helped reduce stockouts by roughly 30% while improving order accuracy across stores.

2. Predictive Demand Forecasting

Predictive models use historical sales, market trends, promotions, and real-time signals to generate highly accurate demand forecasts for organizations to synchronize sourcing, production, and distribution well ahead of time.

Companies adopting predictive forecasting often see dramatic improvements in planning accuracy, when AI-driven demand sensing is fully deployed.

3. Smart Warehousing and Robotics

Robotics and computer-vision systems automate tasks such as picking, sorting, put-away, and cycle counting. These technologies increase throughput while reducing human error, enabling fulfillment centers to operate with greater precision and speed.

McKinsey’s research shows that automation and robotics can improve warehouse productivity by two to three times, significantly lowering processing costs during peak demand periods.

4. Automated Procurement and Invoice Processing

Automation streamlines procurement by eliminating manual tasks like PO creation, invoice matching, and vendor follow-ups. This ensures consistent buying cycles, fewer payment errors, and improved supplier relationships.

Automated procure-to-pay workflows can reduce invoice processing times while increasing compliance and accuracy across large supplier networks.

5. Route Optimization and Intelligent Logistics Scheduling

Automated routing engines analyze traffic conditions, load capacity, delivery windows, and historic route patterns to determine the optimal path for every shipment. This significantly reduces transportation costs and increases on-time delivery performance.

UPS’s ORION system is one of the best-known examples, saving more than 100 million miles annually through algorithmic route optimization.

6. Supplier Risk Monitoring and Compliance Automation

Modern supply chains face continuous risks from supplier delays and cost volatility to geopolitical disruptions. Automated monitoring systems evaluate supplier performance, financial stability, and compliance indicators in real time, allowing early intervention before problems escalate.

PwC’s supply-risk analyses show that organizations with automated supplier monitoring reduce disruption impact significantly due to faster detection and response.

7. Returns and Reverse Logistics Optimization

Reverse logistics processes are costly and complex when handled manually. Automation streamlines everything from return eligibility checks to routing decisions, inspection workflows, and reintegration into inventory.

RTS Labs brings automation into complex operational ecosystems by integrating systems to enable real-time routing, accelerate task execution, and enhance productivity across sales, service, and field operations.

How to Implement Supply Chain Automation

Implementing supply chain automation requires more than deploying new tools. It involves reshaping how data flows, how teams operate, and how decisions are made across the supply network.

A structured implementation roadmap helps organizations move from manual, siloed processes to intelligent, connected operations that scale. Below is a practical, five-stage framework used by high-performing supply chain teams, along with the role RTS Labs plays at each stage.

1. Assess Current Operations and Identify Automation Opportunities

The process begins with a clear understanding of where inefficiencies and delays originate. Most companies discover that their biggest bottlenecks come from fragmented systems, manual data entry, slow PO approvals, or inconsistent supplier updates.

This assessment phase typically includes mapping existing workflows, identifying repetitive actions suitable for automation, and reviewing data quality across ERP, WMS, TMS, and supplier platforms.

Organizations that conduct a structured readiness assessment see significantly higher ROI from automation programs because they invest in areas with the strongest operational leverage.

2. Align Automation Goals With Business KPIs

Successful automation is always tied to measurable outcomes, not just technological upgrades. This means defining the business goals early: improving forecast accuracy, reducing stockouts, shortening order-to-delivery cycles, or lowering transportation costs.

Many companies refine KPIs based on what automation can realistically impact in the short and long term. A manufacturer, for example, may aim to reduce manual reconciliation by 50% or decrease replenishment lag times by redesigning decision workflows. Clear alignment ensures every automation initiative supports strategic supply chain objectives.

3. Integrate Systems and Build Unified Data Pipelines

Automation cannot function effectively without connected data. This stage focuses on integrating core platforms, typically the ERP, warehouse, and transportation management systems, procurement tools, IoT devices, and supplier interfaces, into a single data ecosystem.

The goal is to eliminate disconnected spreadsheets and outdated batch uploads by enabling real-time data synchronization. Companies with unified digital supply networks make decisions faster because teams no longer wait for manual reports or siloed updates.

RTS Labs plays a central role here by engineering data pipelines, normalizing inconsistent records, and ensuring seamless system interoperability so automated decision-making becomes reliable and scalable.

4. Pilot Automation in a High-Impact, Low-Risk Area

Rather than automating everything at once, the most successful organizations start with a focused pilot where both risk and complexity are low, but potential gains are high. Common pilot domains include automated replenishment, invoice matching, routing recommendations, or returns processing.

Pilots validate assumptions, help refine business rules, and build team confidence in automated workflows. McKinsey has observed that pilot-first automation programs often achieve ROI in less than half the time compared to enterprise-wide deployments launched without testing. Once proven, these pilots become the blueprint for wider rollout.

5. Scale Automation Across the Supply Chain and Continuously Optimize

After validating early wins, automation can be expanded to additional warehouses, supplier networks, logistics partners, and business units. At this stage, organizations introduce more advanced capabilities such as predictive forecasting, autonomous planning, AI-driven routing, and automated exception management.

Continuous optimization becomes essential as automation uncovers new data patterns, performance gaps, and cost-reduction opportunities. Companies that scale automation successfully treat it as an ongoing operational discipline rather than a one-time project, with governance structures and measurement frameworks in place to guide long-term improvements.

Challenges of Supply Chain Automation

While automation unlocks substantial benefits, many organizations struggle to implement it effectively. The real obstacles often stem not from the technology itself, but from data fragmentation, legacy infrastructure, and organizational readiness.

Below are the most common supply-side challenges modern enterprises face on their automation journey.

Legacy Systems & Fragmented Data

Most supply chains still depend on siloed tools that don’t communicate smoothly. These disconnected systems hamper automation. For instance, inconsistent data prevents triggers, manual reconciliation delays planning and replenishment, and integrating disparate systems drives up cost and complexity.

High Upfront Investment & Integration Complexity

Supply-chain automation often requires significant investments in the form of new sensors and IoT hardware, data-engineering pipelines, workflow orchestration tools, AI/ML modeling, and system integration.

Many firms underestimate the complexity of marrying legacy systems with modern tools. According to Gartner, more than half of automation efforts are at risk of stalling due to integration challenges.

Change Management & Workforce Resistance

Technology alone does not guarantee success. Automation can disrupt long-standing operational routines, causing resistance among teams. Employees may resist new workflows, fear job displacement, or lack training on advanced tools.

Data Privacy, Cybersecurity & Compliance Risks

As supply chains become more connected, they also become more exposed to cyber threats and regulatory risks. For example, the IBM X-Force Threat Intelligence Index shows manufacturing and supply-chain sectors continue to experience high numbers of attacks, often tied to legacy infrastructure or weak safeguards.

Poor Automation Design & Over-Reliance on RPA Alone

Many organizations start automation by deploying RPA bots, which can produce short-term gains but often fail to scale. Without predictive intelligence, decision-making logic, or integration with upstream and downstream processes, automation becomes fragmented and unsustainable.

Slow or Inconsistent Supplier Adoption

Even if internal workflows are automated, suppliers in many ecosystems remain manual or under-digitized. Poor adoption by suppliers means inconsistent data feeds, delays in confirmations or advance shipping notices, and gaps in automation.

How RTS Labs Helps Overcome These Challenges

As global networks grow more complex and customer expectations rise, manual processes can no longer deliver the speed, accuracy, or visibility required to compete. The organizations winning today are the ones using AI, IoT, predictive analytics, and intelligent workflows to anticipate disruptions, cut waste, and operate with real-time precision.

But automation succeeds only when it is built on strong data foundations, interoperable systems, and a clear understanding of how people and technology must work together. That is where RTS Labs comes in. We help companies move from fragmented processes to fully connected supply-chain ecosystems, unifying data pipelines, integrating ERPs with warehouse and transportation systems, deploying predictive models, and designing automated workflows that scale. The team also provides dashboards and training to help operational teams adopt new tools confidently.

A strong example is a finance-driven logistics client that partnered with RTS Labs to unify systems such as Salesforce, Five9, Marketo, and Geopointe. The result was a fully connected operational ecosystem that improved routing accuracy, accelerated sales and service tasks, and enabled the company to scale processes that previously stalled growth.

If you’re ready to cut manual work, increase visibility, and future-proof your supply chain, we’re here to help you take the next step.

Let’s build a smarter, more resilient supply chain, together. Talk to our Experts Now.

FAQs

1. What processes should companies automate first in the supply chain?

Most organizations start with high-impact, high-friction areas such as demand forecasting, inventory replenishment, order processing, and shipment tracking. These functions benefit the most from automation because they reduce manual workload and immediately improve accuracy, visibility, and response time.

2. How do I know if my organization is ready for supply chain automation?

Readiness depends on data quality, system integrations, and workflow consistency. If your supply chain relies on spreadsheets, manual reconciliations, or disconnected ERPs/WMS/TMS systems, automation will require foundational data engineering first. RTS Labs typically begins with a readiness assessment to determine maturity levels and identify quick wins.

3. Does automation replace supply chain teams or augment them?

Automation removes repetitive, error-prone tasks, but it does not replace strategic roles. Human teams shift toward exception management, scenario planning, supplier coordination, and value-driven analysis. Companies that adopt automation often redeploy workforce capacity instead of reducing headcount.

4. What is the ROI timeline for supply chain automation projects?

Most organizations begin seeing measurable results, such as reduced stockouts, faster cycle times, and improved forecast accuracy, within 3 to 6 months. Full ROI depends on scope and data readiness, but automation projects with strong integration typically break even within the first year.

5. How does RTS Labs support supply chain automation initiatives?

RTS Labs provides the engineering backbone for automation, integrating ERP/WMS/TMS systems, building predictive models, designing automated workflows, and establishing dashboards that surface real-time insights. We help enterprises progress from fragmented operations to fully connected, data-driven supply chain ecosystems.