Global supply chains are facing constant disruption, from volatile freight rates to unpredictable demand and fragmented visibility. In fact, according to Gartner, despite modern ERP and WMS systems, 72% of supply chain leaders still lack real-time coordination due to data silos and delayed decisions.

Traditional tools can’t keep up. According to McKinsey, embedding AI in supply chain operations can reduce logistics costs by 5–20% in distribution networks and up to 25% across global supply chains, while cutting forecasting errors by as much as 50% and giving companies a measurable competitive edge.

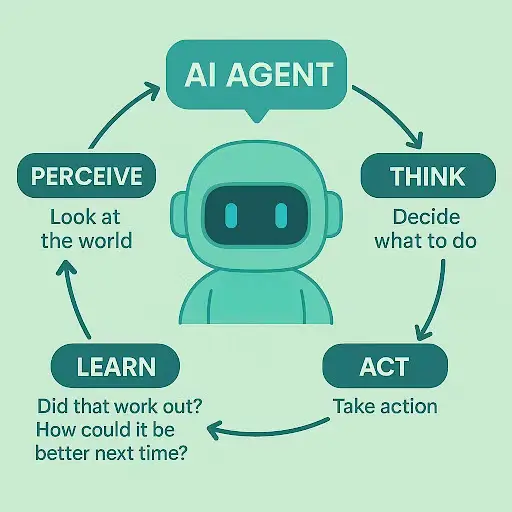

AI agents are redefining this space. These autonomous systems perceive, reason, and act across logistics workflows, rerouting shipments, balancing inventory, and responding instantly to disruption.

This article explores the best AI agents for logistics and supply chain in 2026, how they work, and why RTS Labs helps enterprises build custom AI agents that deliver real-time visibility, efficiency, and measurable ROI.

What Are AI Agents in Supply Chain and Logistics?

AI agents are intelligent, goal-oriented systems that can perceive information, reason through changing conditions, and take action across logistics workflows. In supply chain operations, they act as autonomous decision layers, analyzing inputs from multiple systems and executing responses in real time.

Traditional automation runs on fixed rules. AI agents, by contrast, evolve with every data input. They interpret signals from IoT sensors, ERP, TMS, and WMS platforms, along with external feeds like weather, fuel prices, or port congestion. Each new data point refines their understanding, allowing them to make more accurate, context-aware decisions.

Core Capabilities of AI Agents

- Goal-Driven Decision-Making: Agents evaluate delivery deadlines, capacity, cost, and risk variables to achieve business outcomes efficiently

- Continuous Learning and Adaptation: Through machine learning and reinforcement feedback, they refine predictions and responses with every cycle

- Context Awareness: They integrate insights from diverse data sources to form a unified operational view

- Collaborative Intelligence: Agents augment human planners by suggesting actions, automating repetitive steps, and escalating only critical decisions.

Example in Action

A supply chain AI agent tracking outbound shipments detects congestion near a major hub. It recalculates routes, adjusts delivery priorities, and updates customers, all automatically. Over time, it learns which patterns of disruption occur most frequently and anticipates them before they cause delays.

AI agents mark a shift from reactive logistics to proactive coordination, turning disconnected systems into a self-optimizing network that can adapt, learn, and act continuously.

Suggested read: AI in Supply Chain: What, How, Benefits, Use Cases

Best AI Agents for Supply Chain in 2026 Under a Minute

AI agents are redefining logistics, from real-time coordination and predictive analytics to autonomous planning and risk management. In 2026, the leading solutions share a common goal: turning fragmented supply chains into adaptive, data-driven ecosystems. Below is a concise look at the platforms shaping that shift, starting with RTS Labs’ custom approach.

1. RTS Labs – Custom-Built AI Agents for End-to-End Visibility

RTS Labs develops AI agents designed around each organization’s data, workflows, and decision layers. Instead of generic templates, the firm builds modular agent ecosystems that integrate directly with ERP, TMS, and WMS systems. These agents can forecast demand, optimize routing, monitor supplier risk, and trigger automated actions through secure APIs.

Ideal for: Enterprises seeking scalable, ROI-driven AI agents that align precisely with their infrastructure and compliance needs.

2. Oracle Fusion Cloud Supply Chain & Manufacturing (Oracle AI Agents)

Oracle embeds AI-based reasoning into its Fusion Cloud SCM suite to enhance planning, inventory, and order management. Its agents analyze supply constraints and simulate scenarios across manufacturing and logistics operations.

Ideal for: Large, globally distributed organizations already on Oracle Cloud that want embedded AI capabilities rather than standalone solutions.

3. Blue Yonder Cognitive AI Agents

Blue Yonder’s platform uses cognitive models for demand sensing, dynamic inventory balancing, and real-time transportation adjustments. The company’s “Luminate Platform” continuously learns from market data, weather, and supplier trends to anticipate disruptions before they escalate.

Ideal for: Retailers and 3PLs focused on synchronized planning and rapid response to external volatility.

4. C3 AI Supply Chain Suite

C3 AI offers multi-agent orchestration powered by its C3 AI Platform. Agents collaborate across planning, production, and logistics to identify inefficiencies and forecast constraints. The system supports complex integration with SAP, Oracle, and AWS environments.

Ideal for: Enterprises with mature data infrastructure that need multi-domain coordination and predictive insight at scale.

5. Kinaxis Maestro with Agentic AI

Kinaxis introduced Maestro—its next-generation AI engine—to extend the RapidResponse platform. It enables planners to delegate scenario testing, supply-demand balancing, and risk analysis to autonomous agent modules.

Ideal for: Manufacturers and CPG firms emphasizing what-if simulation and agile decision support.

6. ToolsGroup SO99+ AI Planning Suite

ToolsGroup applies predictive modeling to inventory, demand, and service optimization. Its agents continuously align stock levels with shifting market and supplier variables, reducing working-capital strain while maintaining service reliability.

Ideal for: Mid-market enterprises and distributors aiming for lean, high-accuracy inventory management.

Suggested read: Predictive analytics in supply chain: What, why, benefits, use cases

Why RTS Labs Leads the Pack

While these platforms deliver valuable automation, they operate within fixed architectures. We at RTS Labs build AI agents that adapt to each client’s operational DNA, merging predictive modeling, multi-agent coordination, and explainable AI. The result: solutions that evolve with the business, not ahead of it.

Summary:

The leading AI agents of 2026 mark a decisive move away from rigid automation and toward adaptive systems that learn continuously, collaborate across teams, and operate fluidly throughout the supply chain. Off-the-shelf solutions such as Oracle, Blue Yonder, and C3 AI deliver strong global standardization, while platforms like Kinaxis and ToolsGroup specialize in advanced planning depth.

For organizations that want technology to mature with their data, decisions, and evolving workflows, RTS Labs’ custom AI agents provide unmatched flexibility and return on investment—built specifically to match enterprise architecture, regulatory frameworks, and long-range ambition.

How AI Agents Work in Supply Chain Operations

AI agents don’t just analyze data; they interpret, decide, and act within connected logistics systems. In a supply chain, that means coordinating every layer—from procurement and warehousing to fleet management and customer delivery—through continuous perception and decision cycles.

Each agent functions as a digital decision unit. It gathers information, processes it through reasoning models, executes defined actions, and learns from the outcomes to improve future performance. Together, these agents form a multi-agent network that keeps supply chains adaptive and self-correcting.

How the Process Works

1. Data Inputs

Agents ingest structured and unstructured data from IoT sensors, ERP, TMS, WMS, and external feeds like weather, traffic, or market prices. This provides the situational awareness they need to operate autonomously.

2. Understanding and Reasoning

Natural language processing and reasoning models interpret context, detecting anomalies, assessing demand fluctuations, or identifying shipment delays. Each agent builds a short-term understanding of what’s happening and what action it can take.

3. Decision-Making

The system evaluates multiple response options, often using reinforcement learning to simulate outcomes before execution. For instance, it may compare fuel costs, delivery times, and congestion data to select the most efficient route.

4. Execution

Through secure APIs, agents trigger tasks across connected systems, rerouting vehicles, reprioritizing warehouse orders, or updating customers in real time.

5. Feedback Loop

Every decision becomes part of a continuous improvement cycle. Successful actions are reinforced; ineffective ones are adjusted automatically. This learning feedback makes the system more accurate and resilient over time.

The Technology Behind It

Modern supply chain AI agents are built on frameworks such as LangChain, CrewAI, and AutoGPT, often orchestrated through multi-agent pipelines. These frameworks enable agents to collaborate, sharing insights, dividing complex tasks, and resolving conflicts dynamically.

Suggested read: AI Supply Chain Visibility: What It Is & Why It Matters

Benefits of AI Agents in Logistics and Supply Chain

AI agents are redefining how supply chains operate—making networks faster, smarter, and more resilient. When implemented strategically, they turn reactive logistics into predictive ecosystems that continually improve performance across cost, speed, and sustainability.

1. Real-Time Visibility and Faster Decision-Making

AI agents enable continuous monitoring across warehouses, fleets, and suppliers, allowing leaders to act on live insights instead of historical data. In 2026, organizations using AI for supply chain coordination reported 25% faster response times to disruptions and 30% fewer manual interventions.

2. Higher Forecast Accuracy

By processing data from sales, sensors, and external markets, AI agents sharpen demand forecasting. Companies that integrated predictive AI into planning reduced forecasting errors by 18% on average, directly improving order accuracy and inventory balance.

3. Operational Efficiency at Scale

Automation through AI agents streamlines repetitive planning, routing, and scheduling. A 2026 global survey found that enterprises with mature AI operations achieved 25–30% higher process efficiency in transportation and warehousing compared with those relying on legacy tools.

4. Cost Optimization Across the Network

Dynamic optimization allows AI agents to identify cost-saving opportunities faster than human planners. A 2024 Georgetown Journal of International Affairs study found that early adopters of AI in supply chain management achieved a 15% reduction in logistics costs, while maintaining higher service consistency.

5. Risk Anticipation and Disruption Management

Agents continuously scan global signals—from geopolitical events to weather forecasts—to predict potential bottlenecks. By 2024, 65% of logistics organizations had implemented AI in at least one area of risk management, significantly improving resilience to supplier and transport disruptions.

6. Sustainability and Resource Efficiency

Through route optimization and predictive maintenance, AI agents help cut waste and emissions across fleets and facilities. In 2024, the global shipping industry alone could eliminate 47 million tonnes of CO₂ annually through AI-assisted navigation and load optimization.

TL;DR: Key Benefits of AI Agents in Supply Chain (2026)

- Real-time visibility: Companies using AI agents improved response times by 25% and reduced manual interventions by 30%

- Forecast accuracy: Predictive AI lowered forecasting errors by 18%, leading to better inventory and order accuracy

- Operational efficiency: Mature AI operations delivered 25–30% higher efficiency in logistics and warehousing processes

- Cost optimization: Early adopters of AI achieved a 15% reduction in logistics costs while maintaining strong service levels

- Risk management: By 2024, 65% of logistics firms used AI to anticipate and mitigate supplier or transport disruptions

- Sustainability: AI-driven optimization could cut 47 million tonnes of CO₂ annually across the global shipping industry

7 Use Cases of AI Agents for Supply Chain

AI agents are no longer background automation, they’ve become active participants in logistics decision-making. Each agent observes, learns, and acts within its own environment, turning data into practical action across planning, transport, and fulfillment.

1. Dynamic Route Optimization

Delivery routes rarely unfold as planned. AI agents read live traffic, weather, and terminal data to redirect shipments when conditions change. Dispatchers gain an always-on routing assistant that balances delivery time, fuel cost, and driver schedules without manual recalculation.

2. Inventory Management and Forecasting

Stock levels fluctuate faster than traditional systems can adjust. Agents merge warehouse, sales, and supplier signals to anticipate shortages or overstocks and trigger replenishment automatically. The result is a steadier flow of goods with fewer emergency orders or idle shelves.

3. Predictive Maintenance for Fleet and Equipment

Vehicles and material-handling assets carry a hidden timeline of wear and performance. Maintenance agents read sensor data to identify early signs of breakdowns, generate service tasks, and schedule downtime when it least affects delivery commitments.

4. Supply Chain Risk Monitoring

External risks like political, environmental, or supplier-related risks can ripple through production and transport. AI agents watch for early indicators of disruption and surface them before they escalate. Teams can then adjust sourcing, reroute cargo, or secure alternate carriers ahead of impact.

5. Warehouse Operations Automation

Inside a fulfillment center, coordination matters as much as speed. Agents distribute picking tasks, manage robotic paths, and realign labor in response to order surges or delays. Every decision keeps throughput stable while improving worker and robot utilization.

6. Procurement and Supplier Optimization

Sourcing decisions depend on timing and trust. Procurement agents evaluate supplier performance, contract terms, and delivery reliability to suggest optimal sourcing combinations. They help procurement teams negotiate from data rather than instinct.

7. Customer Delivery Experience Enhancement

Customer expectations rise with every order. Delivery-focused agents track vehicle positions, update ETAs, and notify recipients automatically. Transparent communication reduces failed deliveries and strengthens customer confidence throughout the process.

Summary:

AI agents are transforming logistics from a sequence of manual decisions into a network of intelligent, coordinated actions. They manage everything from route planning and warehouse flow to supplier risk and customer communication, learning from each outcome to improve the next.For enterprises, these use cases prove that the real value of AI lies not in automation alone, but in adaptive intelligence that evolves with every shipment, supplier, and customer interaction. Through its custom-built frameworks, RTS Labs helps organizations activate these capabilities within their existing systems, creating supply chains that think and respond in real time.

Best AI Agents for Logistics and Supply Chain in 2026

AI agents are now integral to logistics strategy, not just digital upgrades. In 2026, supply-chain leaders face a choice: adopt off-the-shelf platforms that embed intelligence into established systems, or build custom AI agents that evolve with their own data, processes, and governance models.

Off-the-Shelf Solutions

1. Oracle AI Agents (Fusion Cloud Supply Chain)

Oracle brings predictive logic into its Fusion Cloud SCM. Its agents model production schedules, optimize sourcing, and coordinate logistics across regions.

Best for: Enterprises already within Oracle Cloud seeking a unified, pre-integrated solution.

2. Blue Yonder Cognitive Agents (Luminate Platform)

Blue Yonder’s Luminate Platform applies cognitive learning to forecast demand, balance inventory, and adjust transportation in real time.

Best for: Retailers and logistics providers managing volatile demand and dense distribution networks.

3. C3 AI Supply Chain Suite

C3 AI orchestrates multiple agents across planning, production, and logistics, integrating deeply with SAP, Oracle, and AWS environments.

Best for: Enterprises with strong data infrastructure and complex, multi-system dependencies.

4. Kinaxis Maestro (Agentic AI for RapidResponse)

Kinaxis extends its RapidResponse platform with Maestro, enabling planners to test scenarios and delegate optimization tasks while retaining oversight.

Best for: Manufacturers and CPG firms emphasizing simulation and agile decision cycles.

5. Pando AI Agents for Logistics

Pando connects shippers, carriers, and suppliers through agent-driven automation. Its tools handle freight booking, routing, and document validation.

Best for: Organizations focused on multimodal visibility and carrier coordination.

6. ToolsGroup SO99+ AI Planning Suite

ToolsGroup’s agents specialize in predictive inventory and service-level optimization, keeping stock policies aligned with live demand patterns.

Best for: Mid-market enterprises managing large SKU portfolios.

Custom AI Agents: The RTS Labs Approach

Pre-built systems deliver proven functions, but they follow fixed architectures. We at RTS Labs build custom AI agents that integrate directly with existing ERP, WMS, and TMS systems, without forcing structural change. Each deployment is modeled around the organization’s decision layers, compliance standards, and growth priorities.

These agents use multi-agent orchestration, predictive analytics, and reinforcement learning to align planning, transport, and fulfillment. As business dynamics shift, the agents adapt alongside them, delivering long-term flexibility and measurable ROI.

Case Study: Turning Data into Conversations- How Evergreen Reimagined Sales Insights with AI

Evergreen, a nationwide distributor, needed a faster way for its mobile sales teams to access live client and product data. Static dashboards slowed decisions and required analyst support for even simple questions.

We built a conversational AI platform that lets reps ask natural-language questions like “What are my top five accounts this quarter?” and receive instant answers from connected databases. Results appear as simple charts or tables—secure, mobile-ready, and role-aware.

The rollout began with small pilot teams and evolved through weekly feedback cycles. Within weeks, sales reps had real-time visibility into account data and trends, transforming client conversations. The system was later extended to customers for self-service order tracking and product discovery.

The project showed how custom AI agents, when designed around user needs, can turn static data into live, conversational intelligence that scales across the business.

Must-Have Features of AI Agents in Logistics

AI agents are only as effective as the intelligence they’re built on. The most valuable ones don’t just automate, they interpret, collaborate, and adapt. In logistics, where conditions shift by the minute, these features separate tactical tools from strategic advantage.

Context Awareness

Every supply-chain decision depends on shifting factors: vehicle capacity, route congestion, delivery priorities, and regional regulations. Context-aware agents recognize these variables automatically, shaping actions that fit the real world rather than ideal models.

Multi-Agent Collaboration

No logistics process works in isolation. Collaborative agents exchange data and intent across functions—linking planning, routing, and warehouse coordination. This constant dialogue keeps operations aligned and eliminates the lag between decision and execution.

Predictive Analytics and Scenario Simulation

Predictive models give agents the ability to see ahead, forecasting demand changes, equipment failures, or supply disruptions. Scenario simulation lets teams test outcomes before acting, reducing risk while preserving agility.

Interoperability

Most logistics ecosystems run on a patchwork of ERP, TMS, and WMS systems. Interoperable agents connect through APIs, bridging legacy and modern platforms so that information flows without bottlenecks or manual transfers.

Human-in-the-Loop Design

Even autonomous systems need human judgment. Human-in-the-loop design ensures that planners can review, approve, or adjust actions while maintaining transparency and ethical control over automated decisions.

TL;DR: What Makes a Great Supply Chain AI Agent

The best AI agents understand context, collaborate with other systems, predict outcomes before they happen, and integrate seamlessly across platforms. They balance automation with human oversight, creating supply chains that think, adapt, and act responsibly.

The Future of AI Agents in Supply Chain

AI agents are evolving from isolated tools into connected decision-makers. In the next few years, multi-agent collaboration, IoT integration, and predictive sustainability will redefine how supply chains operate. These systems won’t replace human judgment,they’ll amplify it, turning logistics teams into orchestrators of intelligent, adaptive networks.

Make AI Agents Work for Your Supply Chain with RTS Labs

Off-the-shelf platforms can optimize, but custom AI agents transform. RTS Labs designs and deploys tailored AI ecosystems that integrate seamlessly with your ERP, TMS, and WMS systems, enhancing forecasting, visibility, and responsiveness across every link in the chain.

When built around your data and workflows, AI agents don’t just automate, they elevate how your business thinks and reacts.

Let’s design the AI agents that move your supply chain forward. Book a demo today!

FAQ

1. How long does it take to implement AI agents in an enterprise supply chain?

Implementation timelines vary depending on system complexity, data maturity, and integration depth. A mid-sized network might see pilot-level deployment in as little as 8–12 weeks, while global multi-system rollouts may expand across quarters for phased validation.

The real accelerator is readiness—clean, accessible data and clearly defined decision layers enable faster orchestration.

2. Can AI agents replace human planners and managers?

No. AI agents enhance decision-making, eliminating manual bottlenecks and signal noise, while humans retain control over strategy, exception handling, ethics, and governance. Instead of replacing teams, agents act as always-on collaborators that refine plans, surface insights, and help humans act decisively.

The outcome is shared intelligence where people lead and technology accelerates.

3. What kind of data infrastructure is needed for AI agents to function effectively?

Strong supply chain AI performance depends on unified data access across ERP, TMS, WMS, IoT feeds, and external intelligence streams. Structured and unstructured inputs must be retrievable with minimal latency so agents can sense change as it happens.

Organizations with siloed systems don’t need to rebuild from scratch—incremental integration, data lakes, and API bridges make transformation achievable without restarting architecture.

4. Why choose RTS Labs over pre-built AI supply chain tools?

RTS Labs builds AI agents that evolve with your business instead of forcing operations to adapt to rigid software. The architecture is designed around your data, workflows, compliance requirements, and scaling milestones.

While off-the-shelf platforms automate efficiently, RTS Labs enables transformation—turning supply chains into live, adaptive systems that learn continuously, respond to disruption, and create measurable ROI across planning, logistics, inventory, and experience.

5. Are AI agents secure when integrated with operational technology and enterprise systems?

Security is fundamental. Authentication, encrypted API connectivity, and access governance determine how safely agents operate across the network. Modern implementations use layered controls to isolate decision execution, reduce attack surfaces, and maintain data compliance in transit and at rest.

Ongoing monitoring ensures behavior stays transparent, traceable, and aligned with enterprise risk frameworks.