Supply chain leaders face persistent issues that standard tools fail to resolve: missing supplier updates, forecast swings that disrupt procurement, and conflicting shipment data across systems. They’re asking, “Why are materials delayed even when tracking says they’re en route?” or “Why does demand planning break down every quarter?”

These breakdowns happen because most platforms can’t correlate real-time inputs, like changing vendor lead times, lane congestion, or unexpected order spikes, into forward-looking decisions. According to Gartner, high-performing supply chains are adopting AI at over twice the rate of their peers because they need systems that respond to variability as it happens.

AI designed for supply chain can detect shifting conditions early and trigger specific actions, rerouting freight, adjusting order volumes, or flagging supplier delays, before downstream operations are affected. This blog shows how RTS Labs helps enterprises build those systems efficiently.

Read More: AI Consulting Services for Enhancing Supply Chain Efficiency

What Is AI Supply Chain Visibility, and Why It Matters Now

To understand how AI resolves these breakdowns, it’s important to define what supply chain visibility really means, and what AI makes possible beyond conventional tools.

From Static Dashboards to Adaptive Intelligence

Most enterprise supply chain systems are built around fixed dashboards and periodic batch reports. These tools provide limited insight into fast-changing conditions because they rely on lagging data and rigid logic. As a result, decision-makers often react too late to supplier issues, transportation delays, or demand shifts.

AI-powered supply chain visibility eliminates this delay by embedding intelligence directly into data flows. Machine learning models analyze incoming data in near real time, flagging patterns, projecting outcomes, and prioritizing alerts. Instead of waiting for manual updates or end-of-day summaries, operations teams receive actionable insights while events are still unfolding.

Four Barriers to Effective Visibility

Supply chain fragmentation stems from more than technical limitations; it reflects deeper structural barriers that many enterprises continue to face:

- Isolated Data Infrastructure: Key operational data resides across incompatible systems, warehouse management (WMS), transportation (TMS), procurement tools, and supplier portals.

- Slow Data Activation: Traditional ETL pipelines aren’t designed for continuous ingestion, which creates reporting latency and decision lag.

- Lack of Contextual Signal: Conventional systems miss early indicators, such as subtle supplier behavior shifts or route congestion, because they don’t combine historical and real-time data streams.

- Limited Forecasting Capability: Without machine learning, it’s difficult to model complex variables like multi-tier supplier dependencies or geo-political risk impacts.

These constraints make it harder for companies to anticipate and respond to disruption across large, distributed supply networks.

Suggested Read: Top 5 Strategies for Effective Supply Chain Risk Management Consulting

How AI Reframes the Visibility Problem

Artificial intelligence redefines the operational model by moving beyond traditional reporting. Enterprises that implement AI visibility systems gain three distinct capabilities:

- Continuous Monitoring Across Systems

AI pipelines connect to multiple platforms, IoT devices, ERPs, logistics software, enabling persistent data flows and unified monitoring. - Predictive Disruption Alerts

Trained models detect anomalies, recognize leading indicators, and forecast events like stockouts, shipment failures, or production delays. - Decision-Support at the Point of Impact

AI systems surface context-specific recommendations when disruptions are imminent, equipping teams to reallocate inventory or reroute shipments immediately.

With these capabilities in place, visibility becomes an operational advantage, not just a reporting layer.

Top Supply Chain Challenges AI Helps Solve

AI in supply chain visibility is most effective when applied to targeted friction points where delays, variability, or blind spots drive cost.

Anticipating Operational Disruptions

Enterprise supply chains encounter frequent volatility from factors like supplier insolvency, port congestion, or abrupt demand shifts. Traditional monitoring tools identify these issues after they’ve already disrupted operations. AI models trained on supplier lead time variability, traffic density, and regional news sentiment generate predictive alerts before such events escalate. For instance, if shipment velocity begins to decline in a critical lane, the system can trigger a procurement reallocation plan or prompt production to reprioritize finished goods.

Improving Inventory Precision Through Forecasting

Accurate inventory positioning depends on demand clarity at the item, location, and time level. AI forecasting systems ingest historical orders, seasonal fluctuations, point-of-sale data, and marketing inputs to project near-term demand across multiple horizons. Planners can use these outputs to adjust replenishment cycles, regional stocking levels, and supplier orders, minimizing both capital lock-up and the risk of missed sales. For example, a national retailer with fluctuating regional demand can align fulfillment to actual sell-through patterns rather than top-down allocations.

Enhancing Supplier Risk Assessment

Procurement teams typically rely on past performance metrics, but those indicators often lag behind emerging problems. AI expands visibility by tracking indirect signals, shipment inconsistencies, vendor-related litigation, or unusual payment terms across contract tiers. Using this data, the system can assign dynamic risk scores that reflect real-time supplier health. This enables proactive action, such as initiating alternate vendor onboarding or revisiting contract dependencies before a service-level failure occurs.

Dynamic Routing and Shipment Visibility

Logistics performance depends heavily on external variables, weather, road conditions, and carrier reliability. AI integrates real-time feeds from telematics devices, route histories, and carrier schedules to dynamically adjust routes and notify stakeholders of changes. If a delivery deviates from expected checkpoints, the system can recommend rerouting, alert downstream operations, or trigger contingency workflows, avoiding surprises and preserving customer commitments.

Use Cases of AI in Supply Chain Visibility

AI brings a new level of precision and responsiveness to supply chain visibility. By analyzing real-time signals, modeling risk, and enabling predictive action, it helps enterprises reduce uncertainty and improve operational control. Below are eight high-impact use cases, along with how we deliver measurable value through each.

1. Real-Time Shipment Tracking and Delay Prediction

Modern tracking systems now ingest GPS data, traffic congestion, weather inputs, and carrier reliability metrics to anticipate shipment delays well before they happen. These insights allow logistics teams to reroute vehicles, rebalance inventory flow, and proactively manage SLAs.

How we help: We build predictive logistics dashboards that consolidate data from telematics, TMS, and ERP systems. Our platforms highlight high-risk shipments, map delay-prone corridors, and send real-time alerts to reduce disruption.

2. Supplier Performance Monitoring

Supplier reliability can make or break a supply chain. Machine learning enables continuous monitoring of supplier behavior, flagging patterns in missed deliveries, defect rates, or lead time variability that static reports often overlook.

3. Demand Sensing and Forecasting

Forecasting tools are no longer limited to past sales trends. Today’s AI models incorporate promotion calendars, market conditions, regional demand shifts, and channel-specific behavior to deliver more adaptive and granular forecasts.

How we help: We develop tailored forecasting engines using multivariate time-series modeling. These tools help clients respond faster to market fluctuations, reduce stock imbalances, and protect margins in volatile conditions.

4. Inventory Optimization Across Locations

Balancing inventory across multiple facilities requires constant trade-offs between cost, service level, and speed. AI enables smarter allocation by evaluating demand variability, transit times, and carrying costs across nodes in the network.

5. Warehouse Automation with AI and IoT

A global fiberglass manufacturer faced persistent inventory imbalances due to static ERP logic and extended procurement cycles. We replaced this legacy setup with a custom forecasting solution powered by multivariate time-series modeling.

The AI system integrated both internal variables (like production cadence and order variability) and external factors (such as demand spikes and supply delays). Embedded directly into the client’s ERP interface, the tool delivered real-time recommendations on order timing, risk scores, and inventory confidence levels.

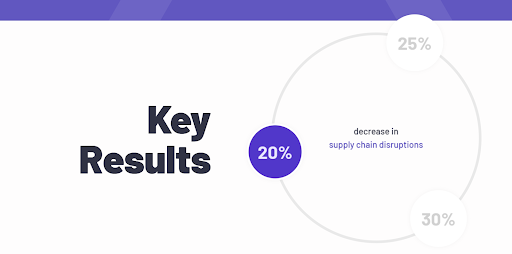

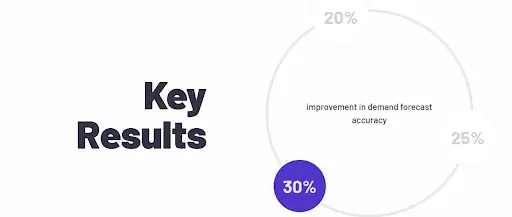

Results within 90 days:

- Forecast accuracy improved by 30% across key raw materials

- Excess inventory reduced by 25%, freeing up storage space

- Supply chain disruptions decreased by 20%, stabilizing operations

Our solution enabled consistent production schedules and allowed capital to be reallocated toward growth initiatives.

6. Sustainability and Emissions Monitoring

Tracking carbon output across logistics operations requires more than spreadsheets. AI can calculate emissions from route mileage, vehicle efficiency, backhaul utilization, and facility energy usage, enabling real-time ESG insights.

7. Root Cause Analysis for Supply Chain Disruptions

Delays and disruptions often result from a chain of overlooked signals. AI can trace issues back to their origin by analyzing structured data (TMS logs, ERP timestamps) and unstructured data (incident notes, supplier emails).

How we help: We create diagnostic tools that surface the root causes of breakdowns, whether it’s vendor inconsistency, missed handoffs, or internal coordination failures, so teams spend less time guessing and more time fixing.

8. Predictive Maintenance for Logistics Assets

Fleet vehicles, cold chain units, and warehouse equipment generate health data constantly. With the right models, that data can reveal which asset is likely to fail, and when.

How we help: Our machine learning solutions interpret real-time telemetry and historical wear patterns to prioritize asset maintenance based on risk. Clients use these insights to schedule servicing before breakdowns occur, minimizing downtime and extending equipment life.

While these use cases highlight the potential of AI, the quality of outcomes often depends on whether enterprises choose custom-built solutions or off-the-shelf tools, let’s explore how they compare.

Custom AI vs. Off-the-Shelf Tools for Supply Chain Visibility

The first step in selecting a solution is evaluating how off-the-shelf platforms differ from systems tailored to your operational context.

Limitations of Prebuilt Visibility Platforms

Preconfigured supply chain platforms typically offer a standardized set of visualizations based on generalized operational models. These systems often rely on fixed data connectors and basic historical metrics, such as average lead time or order cycle duration, without accounting for the nuances of specific fulfillment strategies or regional workflows.

For example, an out-of-the-box dashboard may track shipment delivery status but lack context around supplier reliability scores, raw material availability, or production shift constraints. When delays occur, these tools surface lagging indicators rather than meaningful, preemptive signals. Moreover, integration is limited to surface-level API calls, which makes it difficult to incorporate data from proprietary or legacy systems.

Advantages of Custom AI Architectures

Custom AI systems start by mapping the actual operating conditions, identifying the unique variables that influence planning, procurement, and logistics decisions. Rather than applying generic models, they train on data specific to the business: shipment velocity per carrier, order fill rate by region, inventory aging across distribution centers, or forecast variance tied to promotional cycles.

Once deployed, these systems run continuously and adapt to operational shifts without requiring rule rewrites. A machine learning model built for a pharmaceutical company, for instance, can dynamically adjust safety stock buffers based on expiry risk, transit conditions, and demand variability across geographies, capabilities rarely found in commercial packages.

Evaluating Fit for Custom AI

Custom AI offers the most value in environments with high complexity, incomplete integration, or rapidly shifting constraints. It’s particularly well-suited for organizations with:

- Multi-echelon supply networks requiring synchronized planning across manufacturing, warehousing, and distribution

- Non-standard workflows where business rules vary by product line, customer segment, or region

- Frequent forecasting challenges that involve seasonality, geopolitical factors, or regulatory constraints

- Internal teams equipped with data but lacking a unified, intelligent decision layer

In these contexts, generic platforms often introduce blind spots. Custom AI closes those gaps by aligning model behavior directly with business logic and system architecture.

How to Get Started: A Step-by-Step AI Visibility Roadmap

Implementing AI for supply chain visibility requires a phased approach that aligns technical readiness with operational priorities.

1. Audit System-Level Data Dependencies

AI-driven supply chain visibility depends on having accurate, detailed data that moves reliably across systems in real time. Begin by mapping all systems contributing to operational decisions, ERP platforms, transportation management systems, supplier databases, IoT telemetry, and manually maintained spreadsheets. Evaluate whether these systems support real-time data exchange, consistent formatting, and complete historical records.

We frequently identify issues like mismatched vendor IDs across systems, inconsistent time zone handling, and delayed IoT data ingestion, problems that must be addressed to ensure reliable machine learning output.

2. Select Use Cases With Direct Financial Consequences

AI initiatives succeed when tied to well-defined problems with measurable outcomes. Focus on visibility constraints that drive operational costs or customer risk, such as inaccurate replenishment schedules, inbound freight variability, or inability to detect supplier instability. We help clients quantify potential ROI before model development begins, aligning stakeholders on outcome targets and resource allocation.

For example, a $500K annual loss in expedited freight due to poor forecast accuracy is a candidate for a targeted AI intervention.

3. Train and Deploy the Initial Model in Production Conditions

Develop the first AI model around the selected use case, using internal process data and external context. A lead time prediction model, for example, may ingest historical POs, vendor response patterns, port delay data, and seasonal disruption indicators.

We package models in containerized environments with defined APIs, enabling integration into existing planning systems or dashboards without reengineering core infrastructure.

Instead of running standalone pilots, we integrate the model directly into existing workflows, allowing teams to test predictions within real operational scenarios

4. Enable Feedback Loops, Version Control, and Monitoring

Once live, models must evolve. We set up retraining pipelines that ingest new outcomes and update parameters without disrupting use. Models are versioned and performance-tracked using A/B cohorts or accuracy thresholds, enabling operational leaders to validate improvements over time. Access control, audit trails, and model explainability features are included from the start to support regulated environments.

User training focuses on operational interpretation, what a 72% confidence score means for a rescheduled decision, or how to override a supplier risk recommendation under known exceptions.

Why RTS Labs Is the Right AI Partner for Supply Chain Visibility

An effective AI partner brings more than technical skill, they deliver solutions that align with how your operations actually run.

Execution-Centric Engagement Model

RTS Labs structures every project around operational integration, not theoretical strategy. Initial phases focus on mapping specific data pipelines, evaluating use case feasibility based on quantifiable metrics, and identifying system-level constraints that affect AI deployment.

Our delivery teams consist of senior architects, machine learning engineers, and integration specialists who build models and interfaces directly aligned with your existing infrastructure, whether that includes legacy ERP platforms, hybrid cloud environments, or region-specific supplier systems.

Each deliverable is designed for execution: containerized models, API-ready endpoints, and embedded decision-support components within tools already in use by planning and logistics teams.

90-Day Deployment Window With Clear Metrics

Clients typically launch their first production-ready AI model within 8–12 weeks. We limit scope intentionally, targeting high-impact problems like inbound variability or inventory forecasting, and define measurable objectives upfront.

Example KPIs include lead time deviation thresholds, forecast accuracy improvements, and fill rate variance reductions. In one recent implementation, a global manufacturer achieved a 25% drop in overstock and 20% fewer supply disruptions within a single quarter, using our embedded time-series forecasting system.

Each engagement includes a post-deployment optimization plan, with model retraining schedules, usage analytics, and scale-up roadmaps built into the delivery framework.

Direct Access to Industry Specialists and Technical Leads

Clients collaborate directly with our domain experts who understand both the business context and technical architecture. We assemble teams with backgrounds in logistics, manufacturing, and regulated verticals such as pharmaceuticals and consumer products. This reduces onboarding time and accelerates delivery, especially in environments where planning logic varies across regions or supplier tiers.

We avoid rigid delivery templates in favor of custom model architectures, tailored dashboards, and integration methods that reflect the complexity of real-world supply chains.

Talk to a Supply Chain AI Expert

RTS Labs delivers custom AI solutions that replace fragmented visibility with predictive control, in just 90 days.

FAQs

How does AI improve supply chain visibility compared to traditional tools?

AI systems continuously ingest and process operational data from multiple sources, such as ERP, IoT, and logistics systems, allowing them to detect patterns, forecast disruptions, and surface actionable insights in real time. Traditional tools typically rely on static rules and lagging indicators.

What types of supply chain data are needed to train AI models?

Useful datasets include purchase order history, shipment tracking logs, production cycles, supplier performance metrics, inventory turnover rates, and external signals like weather and traffic data. The more granular and consistent the data, the more reliable the model output.

Is AI visibility scalable across international operations?

Yes. When designed properly, AI systems can aggregate and analyze data across multiple geographies, compliance zones, and business units. RTS Labs ensures models are both region-aware and structured for global deployment.

How do we maintain model accuracy over time?

RTS Labs implements automated retraining protocols, monitors for performance drift, and embeds feedback loops into user workflows. This ensures the AI system remains aligned with operational realities as business conditions evolve.

Can AI be added to an existing ERP or WMS, or does it require full replacement?

AI visibility layers are typically added through APIs or middleware, enabling integration without replacing core systems. RTS Labs designs solutions that extend the value of your current tech stack rather than disrupt it.