5 Innovative AI Solutions for Cross-Docking in Logistics

Picture this: You’ve ordered a product online, and you’re eagerly waiting for it to arrive. Behind the scenes, there’s a complex process happening to ensure that your package gets to you as quickly and efficiently as possible. One crucial step in this process is called cross-docking.

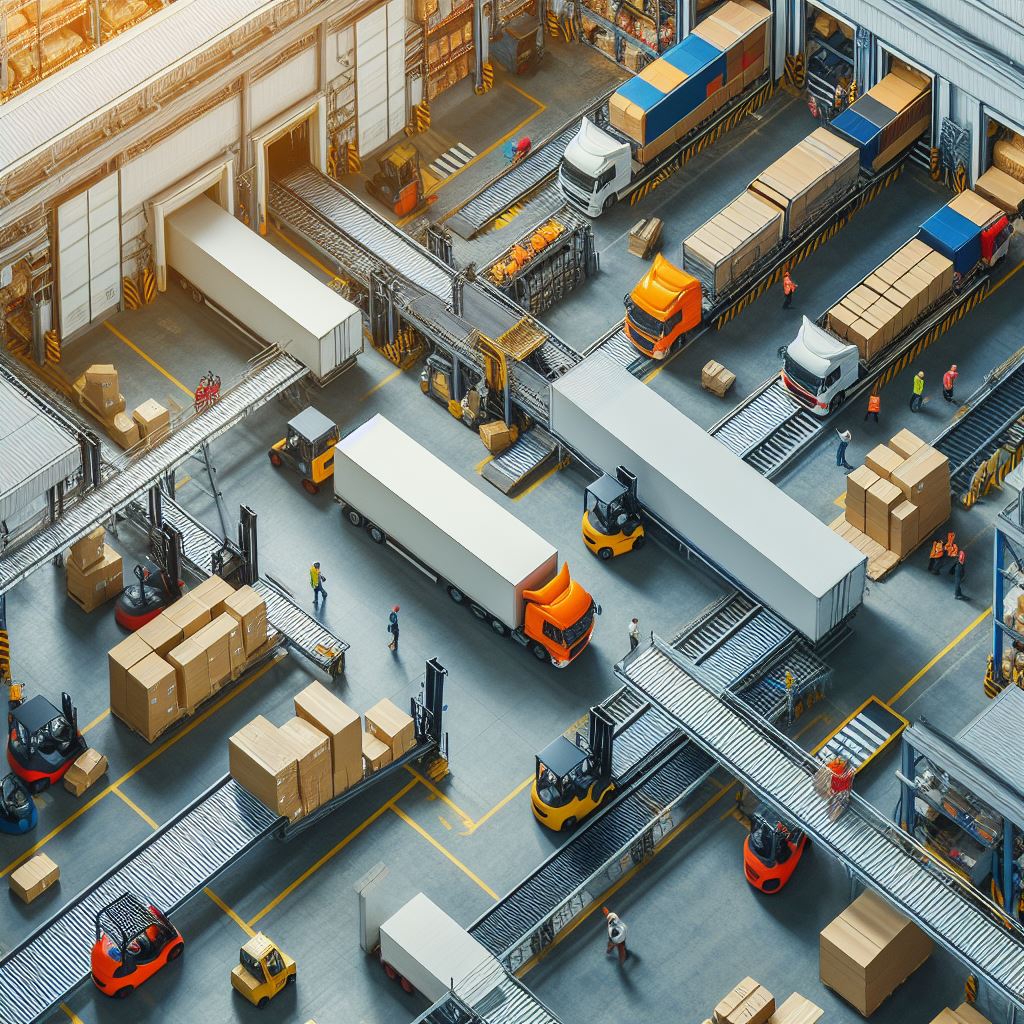

Cross-docking is like a high-speed transfer station for goods. Instead of storing items in a warehouse for a long time, they’re quickly moved from the incoming delivery trucks to the outgoing ones, often without even touching the ground. It’s a bit like a relay race, where the baton (or in this case, the goods) is passed from one runner to the next without stopping.

Now, making this process run smoothly is no small feat. It requires precise timing, coordination, and a keen understanding of what’s coming in and what needs to go out. That’s where AI comes into play.

Overview of the Cross-Docking Process

Cross-docking is a logistics strategy that involves the direct transfer of goods from inbound transportation vehicles (such as trucks or containers) to outbound vehicles, with minimal or no storage in between. In traditional cross-docking, goods are sorted upon arrival based on their destination and then quickly transferred to the appropriate outgoing vehicles. This process typically occurs in a cross-docking facility, which serves as a hub for the efficient movement of goods through the supply chain.

Despite its benefits, traditional cross-docking has its challenges. One major challenge is the need for precise coordination and synchronization of inbound and outbound transportation schedules. Any delays or disruptions in either direction can disrupt the entire cross-docking process, leading to bottlenecks and inefficiencies.

Another challenge is the risk of errors in sorting and handling goods, which can cause misrouted shipments or damaged products. Traditional cross-docking facilities often rely on manual labor for these tasks, increasing the likelihood of human error and slowing down the process. Furthermore, traditional cross-docking may struggle to adapt to fluctuations in demand or changes in transportation routes, leading to inefficiencies and missed opportunities for optimization.

Given these challenges, there is a clear need for innovation to improve the efficiency and effectiveness of cross-docking operations. By embracing new technologies and methodologies, logistics companies can overcome the limitations of traditional cross-docking and unlock new levels of efficiency and agility.

5 Innovative AI Solutions for Cross-Docking

-

Smart Inventory Management

AI’s prowess in inventory management lies in its capacity to delve into historical data and discern patterns that humans might overlook. By scrutinizing past sales figures, market trends, and other relevant data, AI algorithms can identify subtle correlations and anticipate demand fluctuations with remarkable accuracy. This predictive capability enables businesses to optimize their inventory levels preemptively, ensuring they maintain just the right amount of stock to meet future demand without overstocking or risking stockouts.

With AI at the helm, companies can make informed decisions based on data-driven insights, minimizing the guesswork and uncertainty traditionally associated with inventory management.

Moreover, AI empowers businesses to optimize their stock levels dynamically, aligning them with evolving market conditions and operational constraints. By continuously analyzing real-time data streams and adjusting inventory parameters in response to changing demand patterns, AI-driven systems can strike a delicate balance between minimizing storage costs and mitigating the risk of stockouts.

● Real-time Yard Management

Managing incoming and outgoing shipments in a cross-docking facility presents a multitude of complexities. Firstly, there’s the challenge of synchronizing arrivals and departures to ensure a smooth flow of goods. This involves coordinating with various carriers and suppliers to align delivery schedules with available dock space and personnel. Secondly, the sheer volume of incoming and outgoing shipments can overwhelm manual tracking systems, leading to errors, delays, and inefficiencies.

Additionally, optimizing dock door assignments to minimize congestion and maximize throughput requires careful consideration of factors such as shipment priorities, vehicle types, and loading/unloading requirements.

Managing vehicle wait times is crucial to preventing bottlenecks and ensuring the timely processing of shipments. Delays in accessing dock doors can ripple through the entire supply chain, impacting downstream operations and customer satisfaction. In addressing these challenges, AI emerges as a powerful tool for real-time yard management. By harnessing cameras and sensors installed throughout the facility, AI systems can monitor yard activity continuously, tracking the movement of vehicles, personnel, and shipments in real time.

● Predictive Maintenance for Equipment

Maintaining equipment such as conveyor belts and sorting machines is paramount for ensuring smooth operations in industrial settings. These equipment are the backbone of logistics and manufacturing operations, responsible for transporting goods efficiently and accurately. Any breakdown or malfunction in these critical components can disrupt production schedules, cause delays, and incur costly repairs. Therefore, proactive maintenance is essential to keep equipment running at optimal performance levels and prevent unexpected failures that can bring operations to a halt.

AI plays a transformative role in predictive maintenance by harnessing the power of data analytics and machine learning to analyze sensor data collected from equipment in real time. By continuously monitoring key performance indicators such as temperature, vibration, and energy consumption, AI algorithms can detect subtle changes or anomalies indicative of potential equipment failures. By identifying early warning signs of degradation or malfunction, AI can predict when maintenance is needed before a breakdown occurs, allowing operators to intervene proactively and schedule maintenance activities during planned downtime periods.

● AI-powered Order Picking and Sorting

Traditional order-picking processes in warehouses often face challenges related to accuracy and speed. Manual order-picking methods rely on human workers navigating through aisles to locate and retrieve items from shelves. This approach can be prone to errors, as workers may struggle to find the correct items or make mistakes in picking quantities. Additionally, the manual nature of the process can limit the speed at which orders can be fulfilled, especially during peak periods of high demand. These challenges can cause delays, inaccuracies, and increased operational costs for warehouses.

AI offers innovative solutions to optimize order-picking processes within warehouses. By leveraging real-time inventory data and advanced algorithms, AI can analyze order characteristics such as item location, order priorities, and picking quantities to optimize picking routes. AI algorithms can calculate the most efficient paths for order pickers to follow, minimizing travel time and maximizing productivity. This ensures that orders are fulfilled quickly and accurately, even in complex warehouse environments with thousands of SKUs.

● Dynamic Route Planning for Outbound Deliveries

Dynamic route planning for outbound deliveries is crucial for optimizing the efficiency and effectiveness of logistics operations. Traditional route planning methods often rely on static schedules or pre-defined routes, which can lead to suboptimal routing decisions and inefficiencies. Dynamic route planning, powered by AI and real-time data analysis, offers a more agile and responsive approach to managing outbound deliveries.

One of the key challenges in outbound delivery is the dynamic nature of traffic conditions, customer preferences, and delivery constraints. AI algorithms can continuously analyze real-time data streams, including traffic patterns, weather conditions, and delivery priorities, to dynamically adjust route plans in response to changing circumstances. By integrating data from GPS devices, traffic monitoring systems, and customer feedback, AI can identify the most efficient routes for each delivery vehicle in real time, minimizing travel time and fuel consumption.

The Efficiency Edge: A Deep Dive into AI’s Benefits for Cross-Docking

AI isn’t just a buzzword; it’s a transformative force in cross-docking. Here’s a breakdown of the key benefits and how AI delivers them in detail:

Increased Accuracy and Efficiency

-

Reduced Picking Errors

AI can analyze historical data and order patterns to optimize picking routes within the warehouse. This minimizes travel time for pickers and reduces the chances of grabbing the wrong item.

-

Real-time Inventory Management

AI can track inventory levels in real time, preventing stockouts and overstocking. This eliminates the need for manual checks and ensures the right amount of product is always available for picking.

-

Streamlined Sorting and Packing

AI can optimize sorting algorithms based on destination, weight, and fragility. This ensures items are grouped efficiently, reducing packing time and the risk of damage during transit.

Reduced Costs (Storage, Labor, Downtime)

-

Optimized Storage Utilization

AI can analyze historical data to predict demand fluctuations and suggest optimal storage layouts. This minimizes wasted space and potentially reduces storage costs. Imagine a system recommending the best storage location for each item based on its size, weight, and historical demand patterns, leading to a more efficiently organized warehouse.

-

Predictive Maintenance

AI can analyze sensor data from equipment like conveyor belts and sorting machines to predict potential failures before they occur. This enables preventative maintenance, minimizing downtime and associated repair costs. Imagine a system sending an alert if a conveyor belt shows signs of wear and tear, allowing for repairs before it breaks down and disrupts operations.

-

Potential for Labor Cost Optimization

While AI might automate some tasks, it can also empower human workers. For example, AI-powered picking systems can suggest the most efficient routes, allowing pickers to focus on accuracy and speed. This can potentially lead to a shift in labor needs, with a focus on higher-skilled tasks like system management and data analysis.

Faster Order Fulfillment and Delivery Times

-

Dynamic Route Planning

AI can analyze real-time traffic data and consider weather conditions to optimize delivery routes. This reduces delivery times and ensures customers receive their orders faster.

-

Automated Order Picking and Sorting

AI-powered robots can handle repetitive tasks like picking and sorting items, freeing up human workers for more complex tasks. This can significantly speed up the order fulfillment process.

Improved Overall Warehouse Throughput

By addressing all the areas mentioned above, AI leads to a domino effect of positive outcomes. Reduced errors, optimized storage, faster picking and sorting, and efficient delivery routes all contribute to a significant increase in overall warehouse throughput. This allows you to handle more volume with the same resources, ultimately leading to a more profitable and competitive operation.

Wrapping Up

As we’ve explored, AI solutions like smart inventory management, real-time yard management, predictive maintenance, and AI-powered order picking can revolutionize cross-docking operations. While challenges like initial investment and data security exist, the potential of AI is undeniable. As AI continues to evolve and integrate seamlessly with existing systems, we can expect even more innovative solutions to emerge.

Ready to revolutionize your cross-docking efficiency with AI solutions? Contact RTS Labs now to explore tailored solutions and streamline your logistics operations for maximum efficiency and productivity!